Challenge/solution

The Challenge of Today

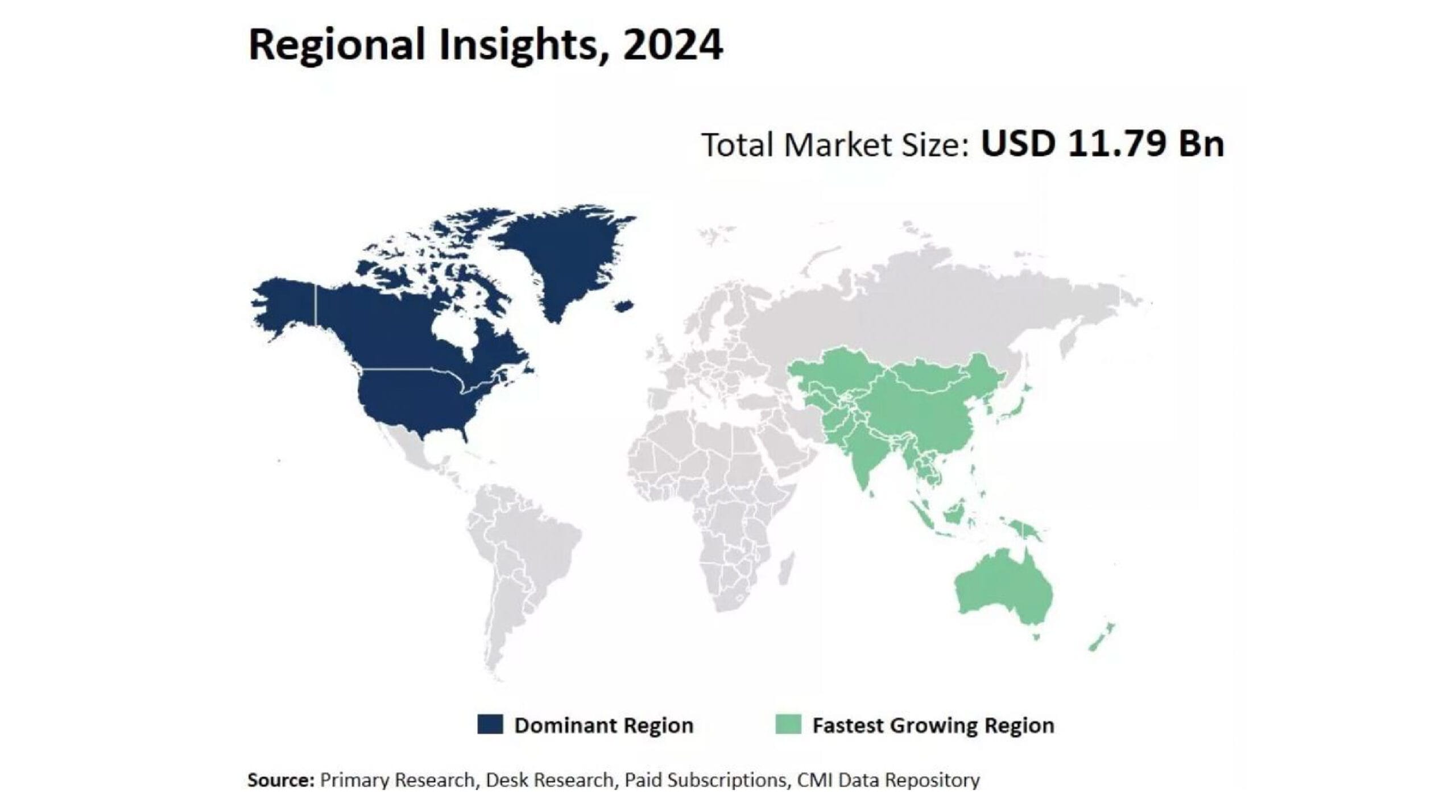

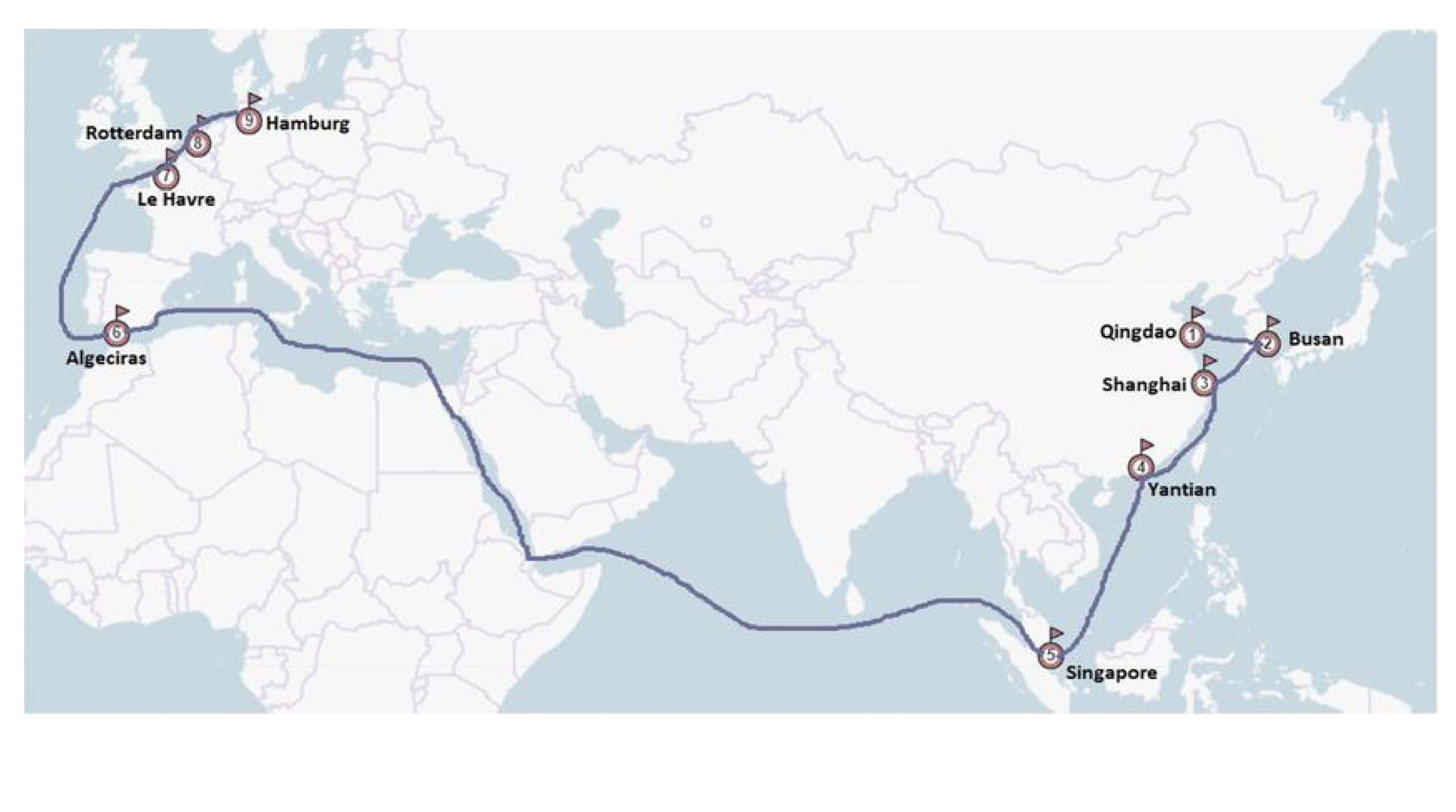

Europe currently depends on China and Korea for 90% of its electrolyte supply, with production and mixing done entirely in Asia. This creates long lead times and exposes companies to quality risks during transport, as electrolytes are highly sensitive to environmental conditions.

• 90% of the electrolyte in Europe comes from China and Korea

• It is made and mixed finished in Asia

• It takes approximately 12 weeks before it arrives to the client in Europe

• sensitivity of electrolyte to normal environment (risk of quality impact from transportation) and/or risk of transporting these goods in masses

Our Solution for Tomorrow

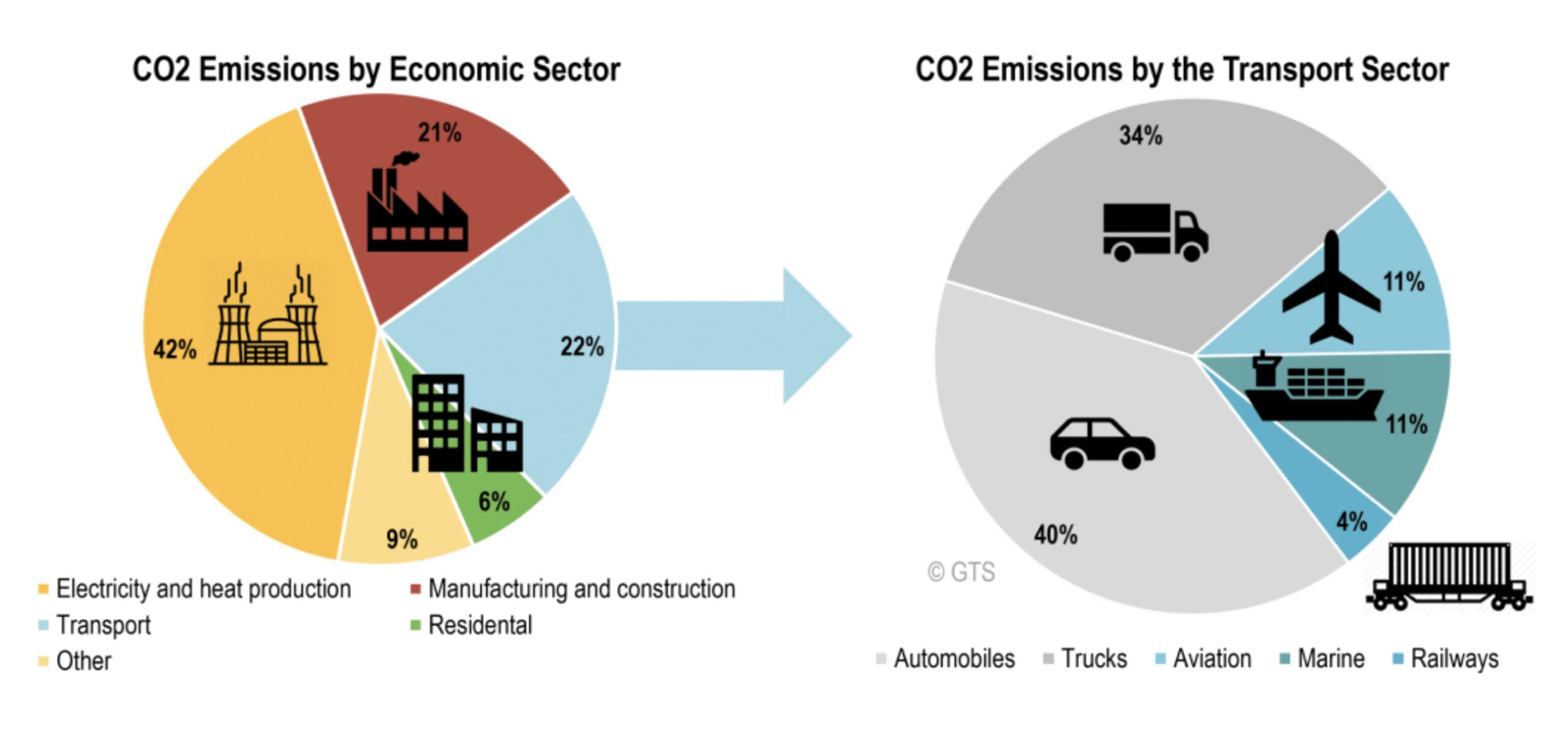

By ensuring local, EU-owned production, companies can reduce GHG emissions by at least 50% within 3 years, guarantee supply security without geopolitical risks, and benefit from proximity to hyperscale manufacturers for rapid delivery.

• Access to critical raw material to succees with battery cell production

• EU pattented recepies

• Assure reduction of minimum 50% GHG emission within 3 years

• Proximity: supply within hours from hyperscale cell manufacturers

• Safe supply without geo political influense

• Competence in mass production

• Contingency security – EU owned and produced

• Competiton safety – proximity to end user